Four Chucks, "0" Tailing Cutting Technology

Four chucks reversing cutting, various clamping methods to achieve zero tailing length, improve material utilization and save costs;

Innovative Four Pneumatic Chucks Design

One button to open the clamp, auto centering, the speed is 3 times that of the electric chuck, reduce loading and unloading time;

Pneumatic opening clamp, large and constant clamping force, heavy tube clamping is not loose or slip, cutting accuracy ensured;

Special support frame to avoid sagging tube deformation, improve the cutting accuracy and prolong the service life of the chuck.

Super Long Tube Process

Load and unload 6 meters of tube as a whole, easy to process long workpieces;

Thanks to four chucks design, it can process and unload the whole 6m long tube and meet your super long tube process demand.

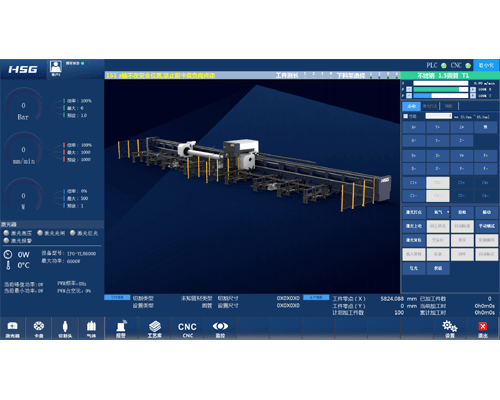

HSG-X9800 Tube Cutting System

Inherit the intelligent HSG-X9000 system, stored with tube drawing library, no programming needed, efficient and time-saving;

Generate processing records and reports automatically, worry-free production and convenient operation;

Unfolded shaped tube graphics as 2D and real-time display cutting paths, more intuitive;

Easy Operation, Powerful Auxiliary Functions

Nearly 100 Kinds of Tube Tenon Joint Processing Database

The system integrates nearly 100 kinds of tube tenon joint processing processes. The tube can be seamless spliced after cutting to provide convenience for the subsequent welding process;

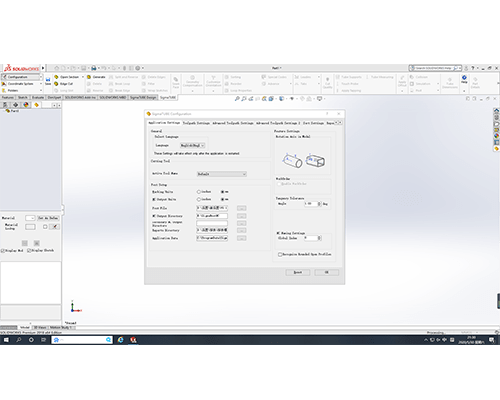

Imported Nesting Software, High Material Utilization Rate

Sigma Tube professional tube nesting software, seamlessly nested with Solidworks drawing software, directly nesting after drawing; Besides the ordinary tubes, it can also nest channel steel, angle steel and other profiles; Path optimization, co-edge cutting, improve efficiency and save costs.

Intelligent Remote Control

One button wireless control: calibration, blowing, simulation, cutting, pause, etc.; Magnetic suction design, put and take at any time, convenient for operation.

Safety Protection Grating

Set a safe distance, once personnel entered by mistake, the machine will stop immediately.

Active Protection System

Anti-collision Protection

The cutting head keeps a safe distance from the cutting surface at any time, and has the function of touch stop function to reduce the risk of collision.

Intelligent Stroke Protection

Auto monitoring of transmission parts’ travelling range. The system can give sensitive feedback and quickly command to stop when abnormal, so as to ensure the safety of the equipment.

Intelligent System Alarm

Equipment can conduct self inspection, main interface can display abnormal alarm, reduce hidden dangers and improve equipment troubleshooting efficiency.

Active Protection System

HSG Laser Protection Design, Safer

Intelligent safety monitoring system, automatically stop operation when protective door is opened, reducing accidents.

Sealed Electrical Cabinet Design, Safer

Advanced Appearance Design

Technical Parameter

| Feature/Model | TH65Plus |

|---|---|

| Round Tube Processing Dim. | Φ20-Φ210mm |

| Square Tube Processing Dim. | 20*20mm-150*150mm |

| Retangle Tube Processing Dim. | Diagonal≤210mm |

| Profile Processing | Yes |

| Max Single Tube Loading Weight | 100kg |

| Max Bundle Loading Weight | 3000kg |

| Chuck Type | Four penumatic chuck |

| Chuck Max. Loading Weight | 100kg |

| Chuck Rotating Speed | 100r/min |

| Max. Moving Speed | 100m/min |

| Max. Acc. Speed | 1.0G |

| Positioning Accuracy | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm |

| Power Protection Grade | IP54 |

| Laser Power | 1500W~3000W |

| Machine Weight | 11500kg |

| Machine Weight (loading structure incl.) | 15000Kg |

| Overall Dimensions (L*W*H)) | 18000×3050×2550mm |

| Overall Dimensions (L*W*H) loading structure incl. | 18000×5050×2550mm |

*The above data is for reference only, subject to the actual product!