P06

-

GT Series Medium And High Power Laser Cutting Machine

GT Series Medium And High Power Laser Cutting Machine

-

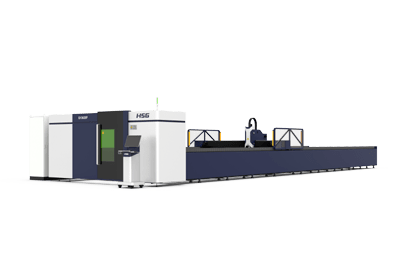

GF Series High-power Large-Format Laser Cutting Machine

GF Series High-power Large-Format Laser Cutting Machine

-

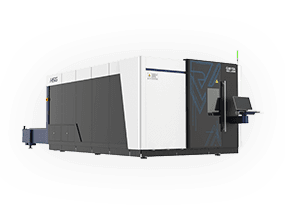

GA/GA PRO SERIES Full-protective Double Exchange Platforms Laser Cutting Machine

GA/GA PRO SERIES Full-protective Double Exchange Platforms Laser Cutting Machine

-

GX Series Double Exchange Platforms Laser Cutting Machine

GX Series Double Exchange Platforms Laser Cutting Machine

-

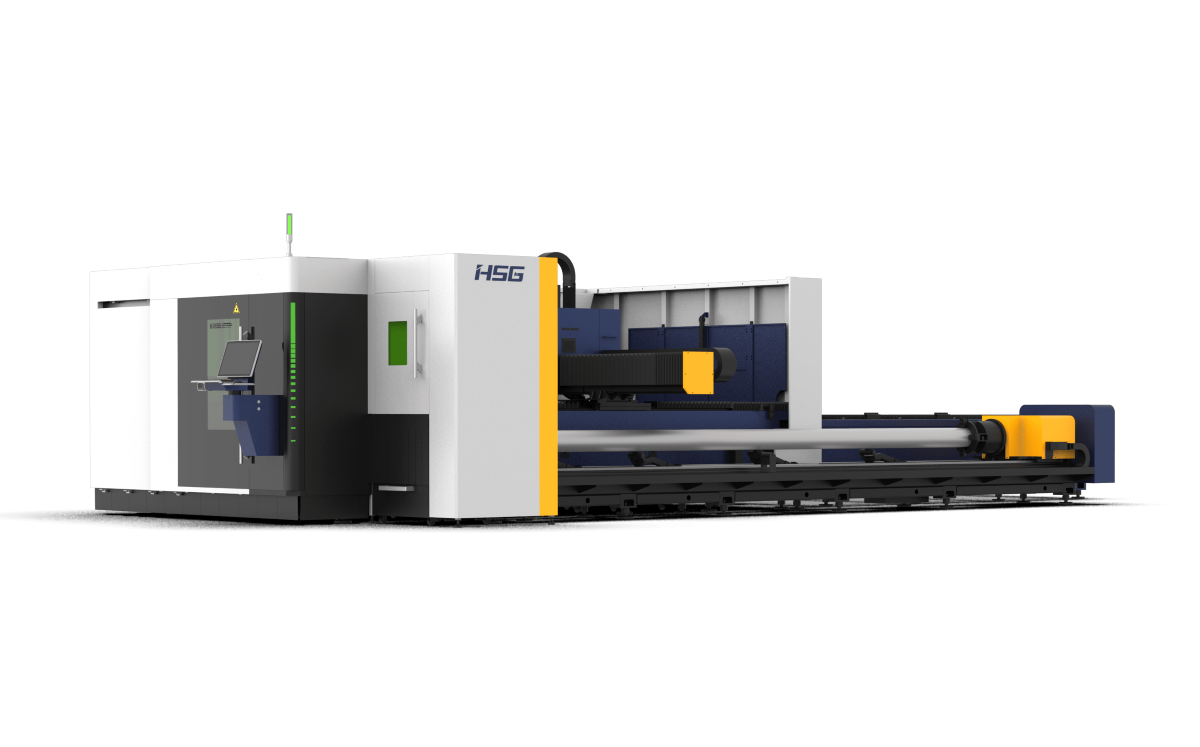

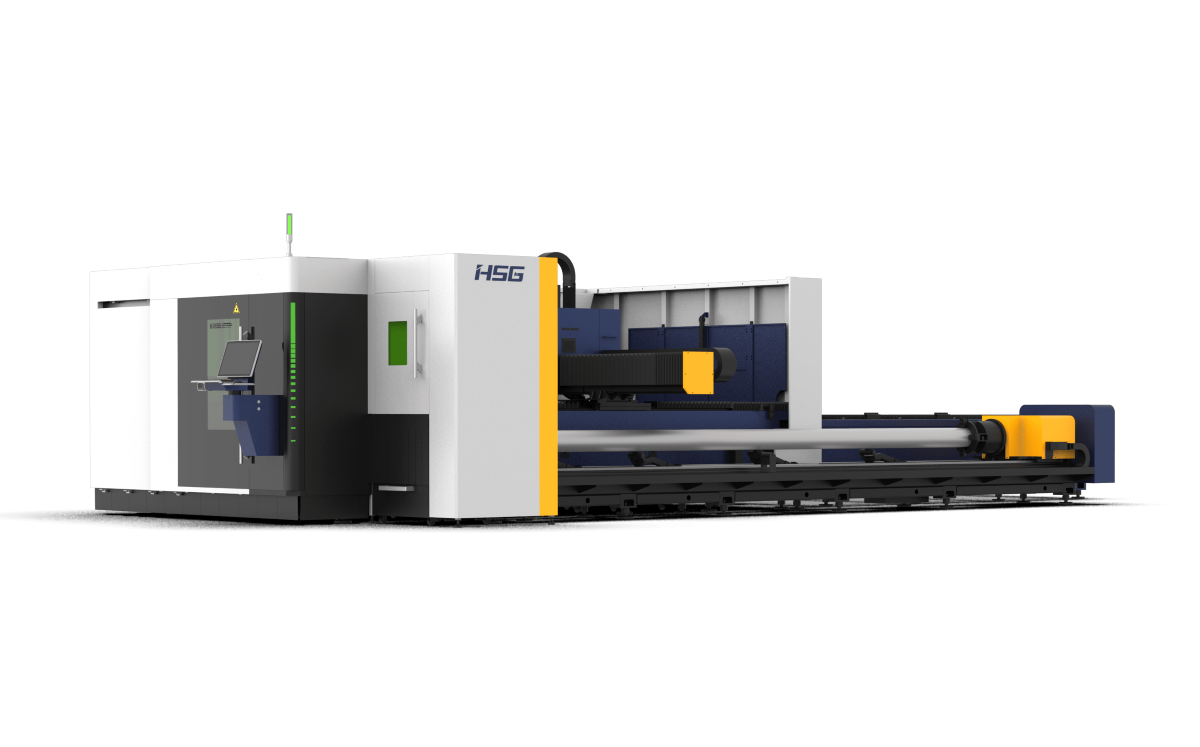

GTE Brand New Medium High Sheet & Tube Metal Cutting Machine

GTE Brand New Medium High Sheet & Tube Metal Cutting Machine

-

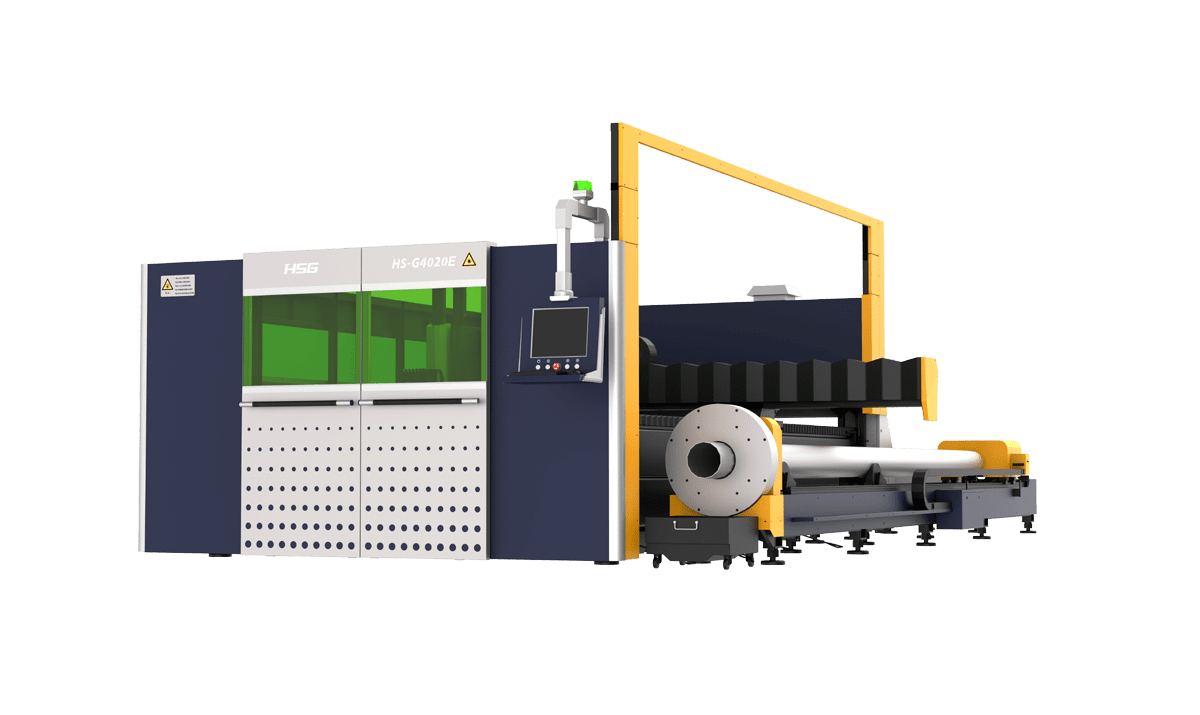

GE Series Double Platforms Sheet & Tube Laser Cutting Machine

GE Series Double Platforms Sheet & Tube Laser Cutting Machine

P10 / P20

-

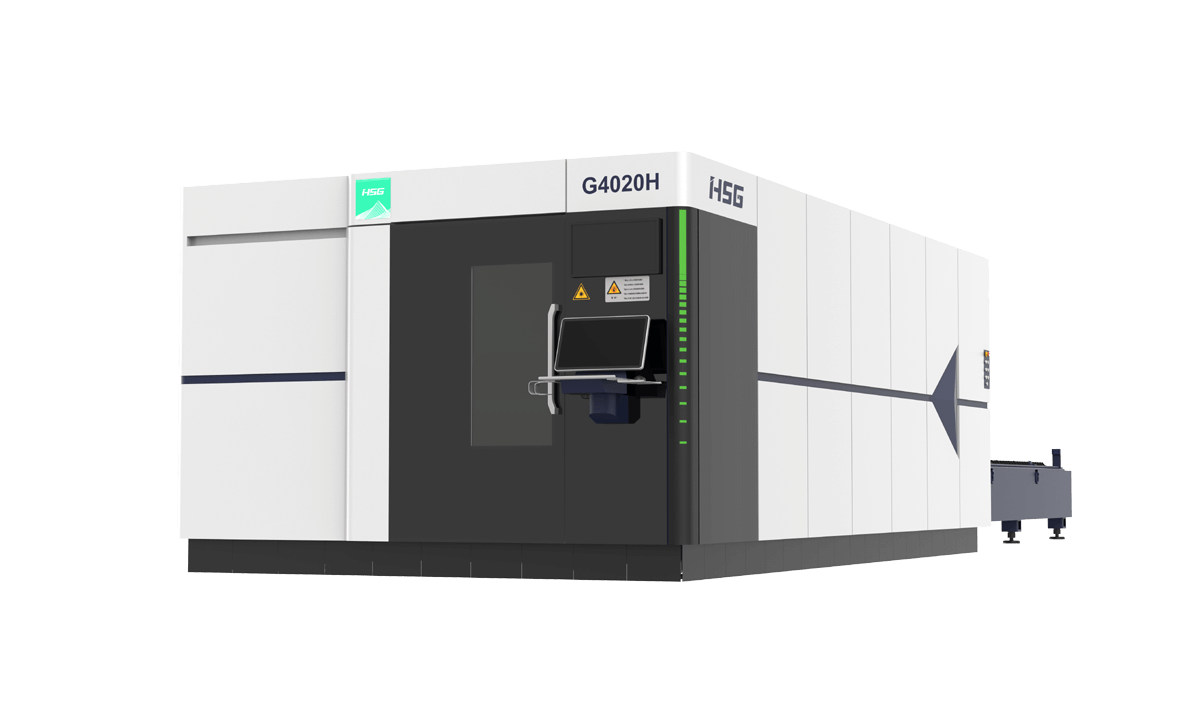

GH Series High Power Laser Cutting Machine

GH Series High Power Laser Cutting Machine

-

GT Series Medium And High Power Laser Cutting Machine

GT Series Medium And High Power Laser Cutting Machine

-

GF Series High-power Large-Format Laser Cutting Machine

GF Series High-power Large-Format Laser Cutting Machine

-

GTE Brand New Medium High Sheet & Tube Metal Cutting Machine

GTE Brand New Medium High Sheet & Tube Metal Cutting Machine

-

GHE-35HQ Series High Power Sheet & Tube Laser Cutting Machine

GHE-35HQ Series High Power Sheet & Tube Laser Cutting Machine

-

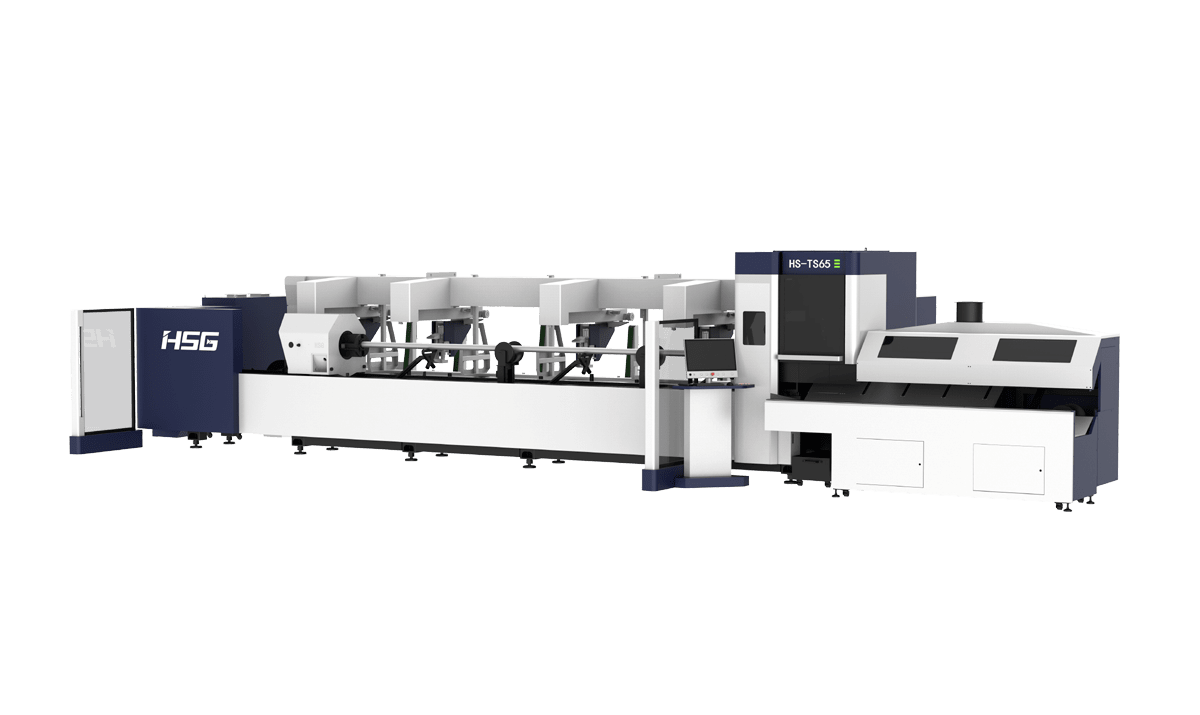

TS65 Series Ultra High Speed Laser Tube Cutting Machine

TS65 Series Ultra High Speed Laser Tube Cutting Machine