As smooth as a mirror, smaller degree of taper, highter precision

Much thicker mirror-like surface

Tackle tiny hold and sharp corner cutting

Save energy and costs

Improve cutting efficiency

Facilitate subsequent processing

What is Mirror-like surface Cutting?

It means that carbon steel is cut with very smooth surface by oxygen, just like a mirror. We call it as “mirror-like surface cutting”. This type of cutting is mainly applicable to medium-to-thick carbon steel.

Apparent Advantages for You

1. MIRROr-LIKE EFFECTS, DEGREE OF TAPER <= 0.18"

Cutting surface is as smooth as a mirrow without any burr or need for subsequent polishing, Compared with general cutting (degree of taper <= 1″), our mirror-like surface cutting keeps its degree of taper withing 0.18″

2. FURTHER REDUCTION IN COSTS

Our mirror-like surface cutting is diametrically opposite to general cutting because it needs small nozzle and low cutting pressure, as thus, oxygen consumption in unit time is much less that that of general cutting, In spite of quality improvement, production costs are greatly reduced

3. FURTHER IMPROVEMENT IN SPEED

The mirror-like surface cutting is accompanied by high cutting speed. For example, cutting20mm carbon steel under 12KW is more than 150% faster than 3kW.

4. TACKLE TINY HOLD AND SHARP CORNER CUTTING

For general cutting, the ratio between material thickness and minimum hold diameter is 0.5, but our high-power-mirror-like surface cutting can shrink to 0.3, that is, minimum hold diameter is reduced from 6mm (3kW) to 4mm (6kW) while cutting 12mm carbon steel. Meanwhile, the overburnt sharp corner will not appear under high power

Why We can Make Mirror-like surface Cutting Come True?

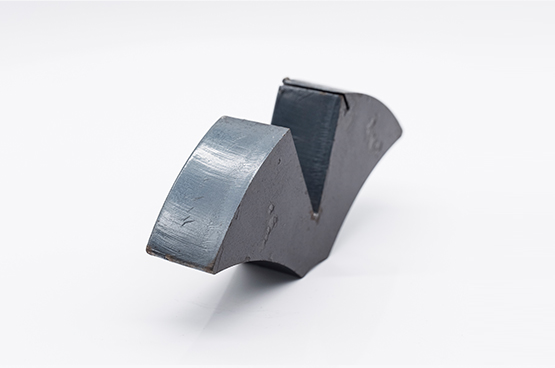

Our ultrasonic single- or double-layer nozzle is only 1.0-1.2mm. Gassing density is highly guaranteed.

Our max. cutting power is 30kW. As we all know, the higher the power, the greater the cutting thickness. Under 12kW, the thickness of mirror-like surface cutting can reach up to 20mm.

The cutting pressure is 0.6-1.2Bar, which can help to avoid overburnt surface caused by overmuch oxygen.

Why We can Make Mirror-like surface Cutting Come True?

| Power | Mirror-like Surface Thickness (mm) | Max. Cutting Thickness (mm) |

|---|---|---|

| 3kw | 8 | 20 |

| 4kw | 10 | 22 |

| 6kw | 12 | 25 |

| 8kw | 16 | 25 |

| 10kw | 20 | 30 |

| 12kw | 20 | 40 |

Tips:

1. The above are conservative data. For well-preserved or high-purity materials, the max. thickness of mirror-like surface reaches 30mm under 12kW.

2. The quality of mirror-like cutting mainly depends on high cutting speed, small nozzle, low nozzle height, low cutting pressure, appropriate power and cutting focus as well as degree of material purity.