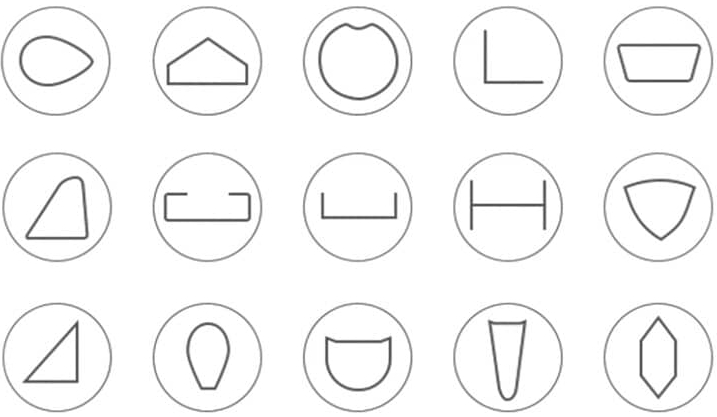

Cut Most of Marketable Special-shaped Tubes

Our tube laser cutting machines can process drop-shaped, triangular, fan-shaped, waist-shaped, D-shaped, L-shaped, C-shaped, trapezoidal, concave tubes, other complex-shaped polygonal tubes, etc.

Intelligent Digital Chucks

Our chucks can feel clamping status and tube size of tubes, offer wireless data transmission and adjust clamping force in self-adaptive way to even clamp special-shaped tubes easily. As thus, small tubes remain unchanged in shape and large tubes are clamped stably.

Anti-collision Laser Cutting Head

The self-developed 3D five-axis cutting head has a function of intelligent collision avoidance and enjoys 360° anti-collision protection. As a result, the cutting head has no collision with irregular edges of special-shaped tubes and will not be destroyed. The probability of production halt is greatly reduced, costs of consumables can be minimized and production efficiency is improved.

Cutting Precision Improved by Multiple Types of Centering

Centering is used for measuring the deviation between tube center and rotating center (B axis) caused by misalignment while clamping tubes. Considering that centering can make sure of cutting track precision, it is essential to make centering for tubes until above deviation is recorded by our control software. Centering is vital for special-shaped tubes. Given this, we offer four-point centering, five-point centering, multiplaner centering, edge-based centering, etc. If fails, manual and advanced manual centering are also practicable to keep cutting precision.

Fast in Speed and High in Quality

For our tube laser cutting machines used for cutting special-shaped tubes, the max. rotating speed of chuck, no-load speed and acceleration are 170r/min, 140m/min and 1.2G respectively. Small tubes are cut tracelessly without any overburnt. Real zero tailing and 45° bevel cutting are also realizable. In addition, cutting cross section is smooth and slagless with no need for subsequent polishing.

TM65 Series Tiny Tube Laser Cutting Machine

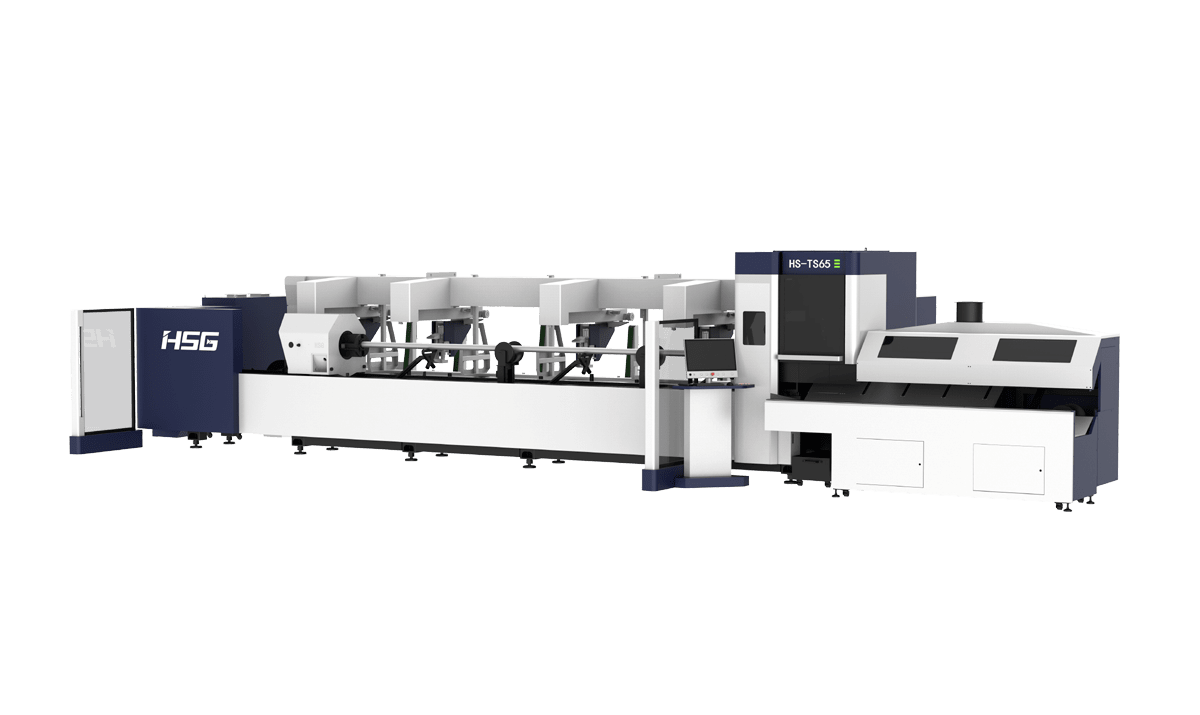

TM65 Series Tiny Tube Laser Cutting Machine  TS65 Series Ultra High Speed Laser Tube Cutting Machine

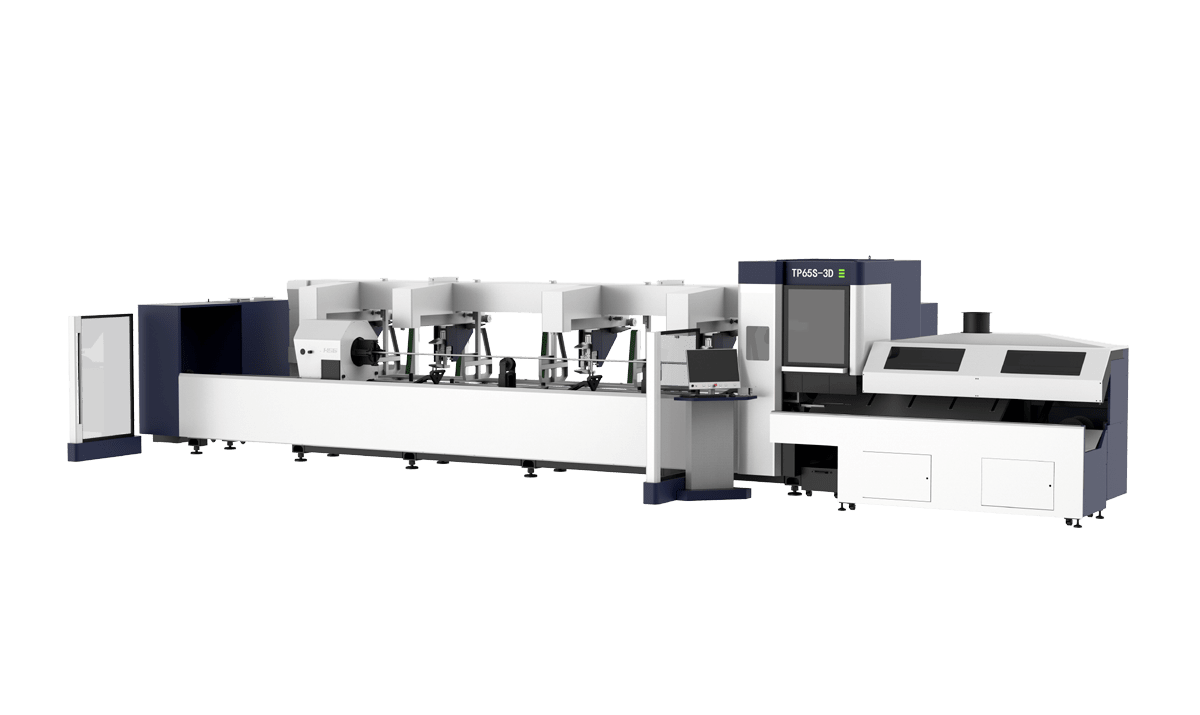

TS65 Series Ultra High Speed Laser Tube Cutting Machine  TP65S Series Groove Tube Laser Cutting Machine

TP65S Series Groove Tube Laser Cutting Machine  TX65Plus Series Heavy Duty Tube Laser Cutting Machine

TX65Plus Series Heavy Duty Tube Laser Cutting Machine