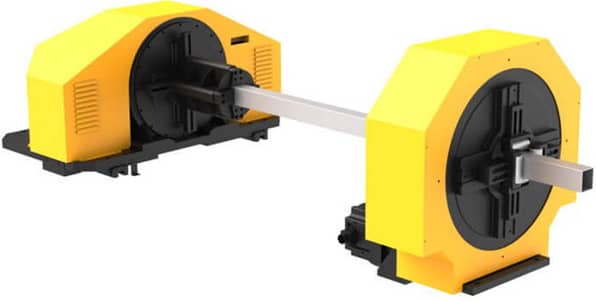

Professional Double Pneumatic Chucks

High efficiency: one key clamping, automatic centering, 3 times of the speed of the electric chuck;

High precision: large and constant clamping force, no loosening of tube, cutting accuracy ensured;

High stability: specialized tube support can avoid tube sagging and deformation, accurate and durable;

Special Cutting Head for Tube Cutting

Smart cutting head specially developed makes various types of tube cutting easier;

Tapered pointed design makes obstacles avoidance easily when cutting shaped tubes;

New collimation and protection lenses, better protection for the core components.

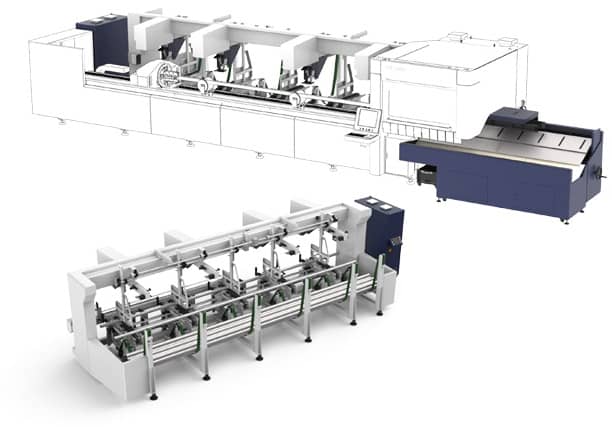

Full Automation, Less Labor Cost

Automatic feeding system, bundle tubes can be intelligently sortied and single tube feeding is completed in one go;

Automatic sorting of finished products and waste, efficient and convenient;

Seamless connection with loading and cutting, no waiting;

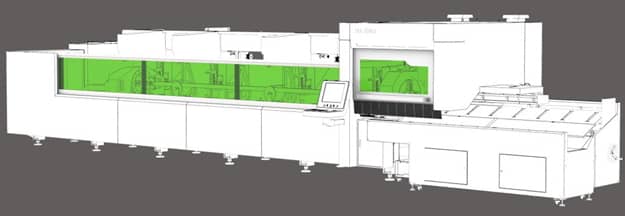

Safety Protection Grating

Set a safe distance, once personnel entered by mistake, the machine will stop immediately.

Easy Operation, Powerful Auxiliary Functions

Self-developed Tube Cutting System

HSGX8800 control system, specially designed for tube cutting, has abundant auxiliary functions for tube processing; Integrated control of core components, intelligent management and convenient operation; Full touch screen operation, responsive and easy to reach with one touch.

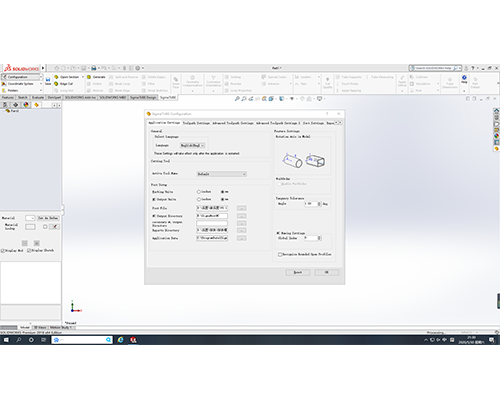

Imported Nesting Software, High Material Utilization Rate, Low Cost

Sigma Tube professional tube nesting software, seamlessly nested with Solidworks software; In addition to ordinary tubes, it can also nest channel steel, angle steel and other profiles; Path optimization, co-edge cutting, improve efficiency and save costs;

Intelligent Remote Control

One button wireless control: calibration, blowing, simulation, cutting, pause, etc.; Magnetic design, put and take at any time.

HSG Laser Design — Product Introduction Video

HSG Laser Protection Design, Safer

Sealed Electrical Cabinet Design, Safer

Advanced Appearance Design

Active Protection System

Anti-collision Protection

The cutting head keeps a safe distance from the cutting surface at any time, and has the touch stop function to reduce the risk of collision.

Intelligent Stroke Protection

Auto monitoring of transmission parts’ travelling range transmission parts. The system can give sensitive feedback and quick command to stop when abnormal, so as to ensure the machine safety.

Intelligent System Alarm

Equipment can conduct self-inspection, main interface can display abnormal alarm, reduce hidden dangers and improve equipment troubleshooting efficiency.Technical Parameter

| Feature/Model | TH65 |

|---|---|

| Round Tube Processing Dim. | Φ20-Φ210mm |

| Square Tube Processing Dim. | 20*20mm-150*150mm |

| Retangle Tube Processing Dim. | Side length: 20-150mm |

| Profile Processing | Yes |

| Max Single Tube Loading Weight | 100kg |

| Max Bundle Loading Weight | 3000kg |

| Chuck Type | Pneumatic chuck |

| Chuck Max. Loading Weight | 100kg |

| Chuck Rotating Speed | 100r/min |

| Max. Moving Speed | 100m/min |

| Max. Acc. Speed | 1.0G |

| Positioning Accuracy | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm |

| Power Protection Grade | IP54 |

| Laser Power | 1500W~3000W |

| Machine Weight | 8000kg |

| Machine Weight (loading structure incl.) | 13000Kg |

| Overall Dimensions (L*W*H)) | 12000×3100×2450mm |

| Overall Dimensions (L*W*H) loading structure incl. | 12000×5000×2450mm |

*The above data is for reference only, subject to the actual product!