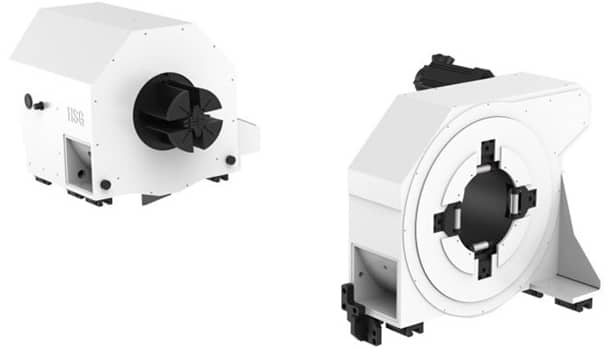

Innovative Digital Chuck

Real-time monitoring of jaw status, closed-loop control, safe and reliable;

Adaptive adjustment of clamping force, no deformation or loose of tube;

Full stroke clamping, no need to replace jaws, convenient operation;

Wide Processing Range

With HSG smart cutting head, easy to cut H steel, I-beam, water-drop-shaped tube, concave and other shaped tubes;

Wide processing range, round tube: ø12mm-ø254mm, square tube: 12mm*12mm-200mm*200mm;

Max loading weight of a single tube: 200KG;

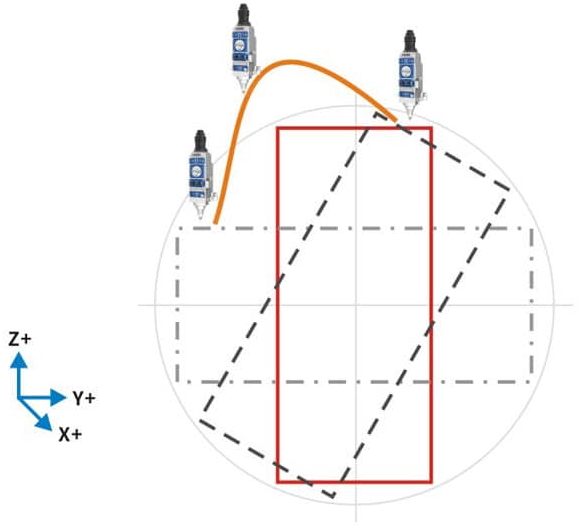

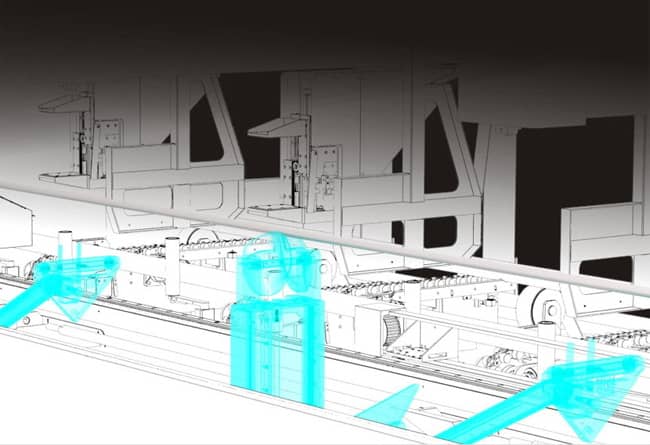

Flying Cutting, Cross-plane Space Frog Leaping Technology

No repeated lifting and descending of the cutting head, cutting efficiency improved.

Flying Cutting, Cross-plane Space Frog Leaping Technology

No repeated lifting and descending of the cutting head, cutting efficiency improved.

Easy Operation, Powerful Auxiliary Functions

Self-developed Tube Cutting System

Abundant auxiliary functions, cater to actual processing needs, worry-free operation; Integrated control of core components, intelligent management and convenient operation; Extremely simplified UI design, simple operation and easy to learn; Intelligent detection of tube deformation, automatic offset compensation of graphics to ensure cutting accuracy; Real-time monitoring of core component status, intelligent diagnosis of malfunction;

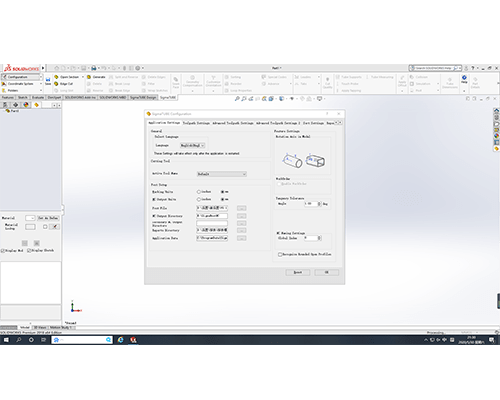

Imported Nesting Software, High Material Utilization Rate, Low Cost

Sigma Tube professional tube nesting software, seamlessly nested with Solidworks software; In addition to ordinary tubes, it can also nest channel steel, angle steel and other profiles; Path optimization, co-edge cutting, improve efficiency and save costs;

Intelligent Remote Control

One button wireless control: calibration, blowing, simulation, cutting, pause, etc.; Magnetic design, put and take at any time, convenient for operation.

Flying Cutting, Cross-plane Space Frog Leaping Technology

No repeated lifting and descending of the cutting head, cutting efficiency improved.

Active Protection System

Anti-collision Protection

The cutting head keeps a safe distance from the cutting surface at any time, and has the touch stop function to reduce the risk of collision.

Intelligent Stroke Protection

Auto monitoring of transmission parts’ travelling range transmission parts. The system can give sensitive feedback and quick command to stop when abnormal, so as to ensure the machine safety.

Intelligent System Alarm

Equipment can conduct self-inspection, main interface can display abnormal alarm, reduce hidden dangers and improve equipment troubleshooting efficiency.

Tube Follow Support and Centering Structure

Rolling support, avoid tube sagging while cutting small tube and heavy tube;

Follow support, the support frame rises and falls automatically with the rotation of the pipe to avoid scratch of the tube surface;

Concave wheel centering structure to prevent tube deflection, to avoid collision betwenn tube and chuck;

HSG Laser Design — Product Introduction Video

HSG Laser Protection Design, Safer

Intelligent safety monitoring system, automatically stop operation when protective door is opened, reducing accidents.

Sealed Electrical Cabinet Design, Safer

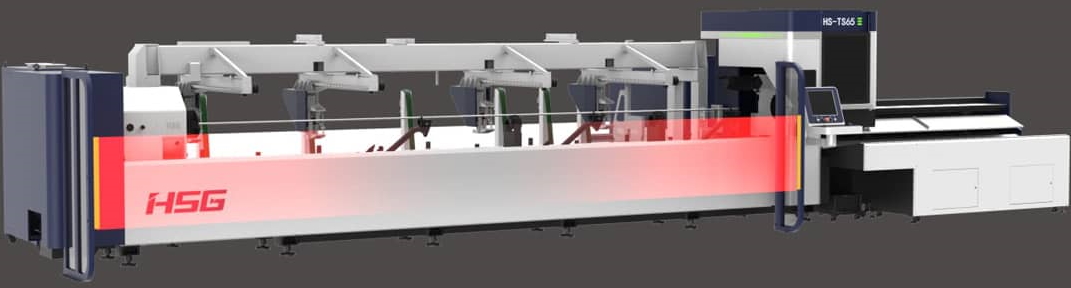

Advanced Appearance Design

Technical Parameter

| Feature/Model | TS65 |

|---|---|

| Round Tube Processing Dim. | Φ12-Φ254mm |

| Square Tube Processing Dim. | 12*12mm-200*200mm |

| Retangle Tube Processing Dim. | Side length:12-200mm |

| Profile Processing | Yes |

| Max Single Tube Loading Weight | 200kg |

| Max Bundle Loading Weight | 3000kg |

| Chuck Type | Pneumatic Chuck |

| Chuck Max. Loading Weight | 200kg |

| Chuck Rotating Speed | 120r/min |

| Max. Moving Speed | 120m/min |

| Max. Acc. Speed | 1.2G |

| Positioning Accuracy | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm |

| Power Protection Grade | IP54 |

| Laser Power | 1500W~4000W |

| Machine Weight | 9500kg |

| Machine Weight (loading structure incl.) | 14700Kg |

| Overall Dimensions (L*W*H)) | 12500×3000×2600mm |

| Overall Dimensions (L*W*H) loading structure incl. | 12500×4700×2600mm |

*The above data is for reference only, subject to the actual product!