Economical Tube Cutting Machine, Low Investment, High Return

Small Footprint

Small size saves plant area, only 2500*9000mm;

Quickly Put Into Production

Easy to install and quick to put into production and creat value for you;

Wide Processing Range

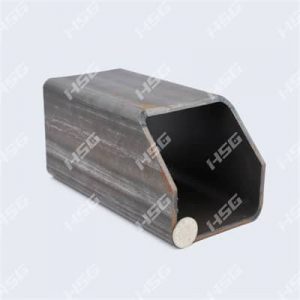

Standard E22: round tube Φ20-210mm, square tube 20-150mm;

Upgraded E35: round tube Φ20-325mm, square tube 20-230mm;

Both can also process channel steel, angle iron and other profiles;

Automatic Double Pneumatic Chuck

High efficiency: one key clamping, automatic centering, 3 times of the speed of the electric chuck, reducing the waiting time of loading and unloading;

High precision: pneumatic clamp, large and constant clamping force, no loosening and slipping of heavy tube, ensuring the cutting accuracy;

High stability: specialized tube support can avoid tube sagging and deformation, improving the cutting accuracy and extending the service life of the chuck;

Simple Operation, Comply with Workers' Habits

Intelligent Tube Cutting System

Tube error detection, automatic correction, to ensure the cutting accuracy; Co-edge cutting function, reduce material waste, save production costs; Corner cutting technique without over-burnt, good section edge quality.

Integrated Gas Circuit

Advanced integrated pneumatic control system, complete set of imported pneumatic components; Connect different auxiliary gases at the same time, flexible selection according to actual operation.

Intelligent Remote Control

One button wireless control: calibration, blowing, simulation, cutting, pause, etc.; magnetic suction design, put and take at any time, convenient for operation.

HSG Laser Design Language --- Product Introduction Video

HSG Laser Protection Design

Sealed Electrical Cabinet Design, Safer

Advanced Appearance Design

Active Protection System

Anti-collision Protection

The cutting head keeps a safe distance from the cutting surface at any time, and has the function of touch stop function to reduce the risk of collision.

Intelligent Stroke Protection

Auto monitoring of transmission parts’ travelling range transmission parts. The system can give sensitive feedback and quickly command to stop when abnormal, so as to ensure the safety of the equipment.

Intelligent System Alarm

Equipment can conduct self-inspection, main interface can display abnormal alarm, reduce hidden dangers and improve equipment troubleshooting efficiency.Technical Parameter

| Feature/Model | E22 | E35 |

|---|---|---|

| Round Tube Processing Dim. | Φ20-Φ210mm | Φ20-Φ325mm |

| Square Tube Processing Dim. | 20*20mm-150*150mm | 20*20mm-230*230mm |

| Retangle Tube Processing Dim. | Diagonal≤210mm | Diagonal≤325mm |

| Profile Processing | Yes | Yes |

| Max Single Tube Loading Weight | 100kg | 100kg |

| Max Bundle Loading Weight | / | / |

| Chuck Type | Pneumatic chuck | Pneumatic chuck |

| Chuck Max. Loading Weight | 100kg | 100kg |

| Chuck Rotating Speed | 50r/min | 50r/min |

| Max. Moving Speed | 60m/min | 60m/min |

| Max. Acc. Speed | 0.5G | 0.5G |

| Positioning Accuracy | ±0.03mm/m | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm | ±0.03mm |

| Power Protection Grade | IP54 | IP54 |

| Laser Power | 1500W~3000W | 1500W~3000W |

| Machine Weight | 4850kg | 5000kg |

| Machine Weight (loading structure incl.) | / | / |

| Overall Dimensions (L*W*H)) | 9000×2100×2400mm | 9000×2100×2400mm |

| Overall Dimensions (L*W*H) loading structure incl. | / | / |

*The above data is for reference only, subject to the actual product!