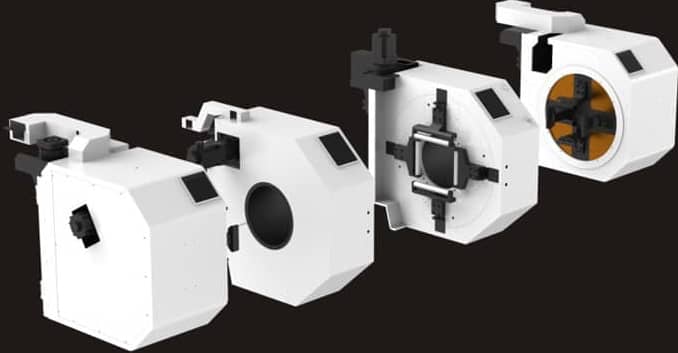

Innovative Four Chucks Technology

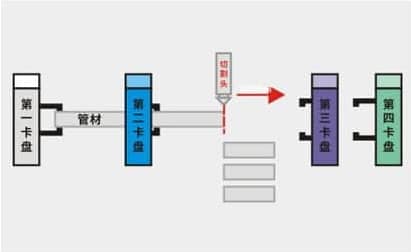

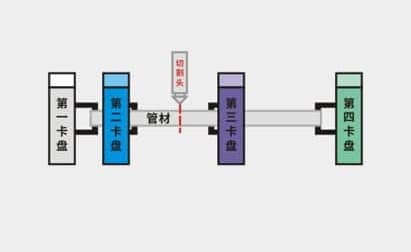

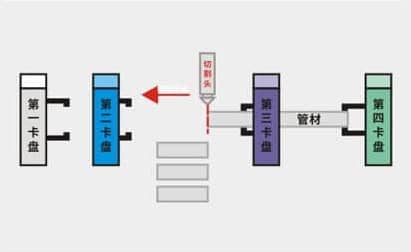

Four chuck reverse cutting, a variety of clamping methods, to achieve zero tailing length, improve material utilization rate and save costs;

Innovative Intelligent Four Chucks Design

Four chuck design: double hydraulic chucks+ double pneumatic chucks, large clamping force of oil cylinder;

For clamping 80mm to 426mm tube, only need to change the jaws once; Intelligent detection of jaw status, easily obtain tube data , automatically match appropriate air pressure and adjust the clamping force;

Power-off Cutting Restart Technology

Adopted Japanese imported servo motor, which contains an absolute encoder to ensure the high performance of the whole machine. It can restart cutting easily according to software memory after power outage.

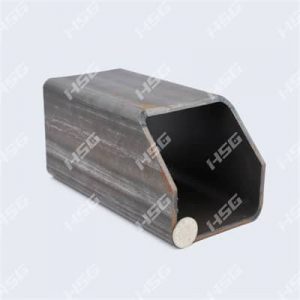

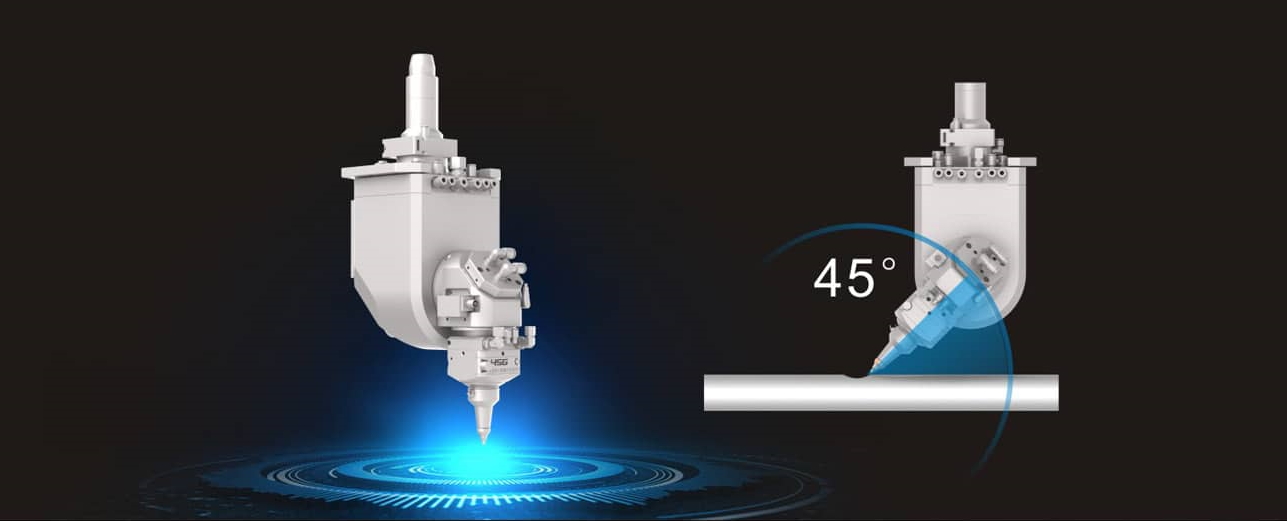

3D 5-Axis Bevel Cutting Head

HSG independent developed height adjuster and three-dimensional five-axis cutting head, providing professional heavy-duty tube cutting solutions, can achieve maximum 45 ° bevel cutting.

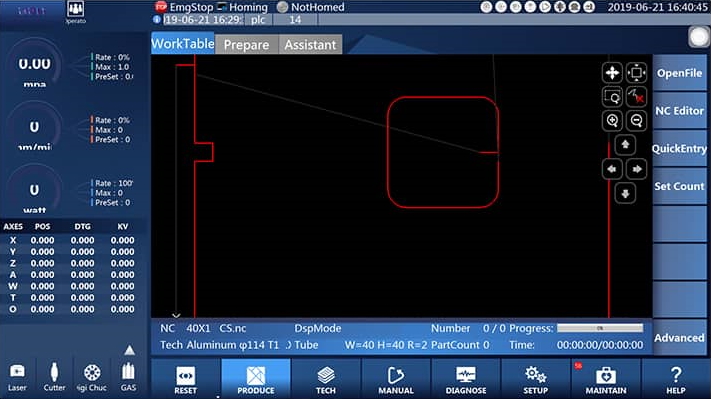

HSG-X9800 Tube Cutting System

Inherit the intelligent HSG-X9000 system, more specialized in tube cutting; stored with tube drawing library, no programming needed;

Automatically generate processing records and reports, worry-free production;

Unfolded shaped tube graphics as 2D and real-time display cutting paths, more intuitive; arbitrary entry of program, convenient operation;

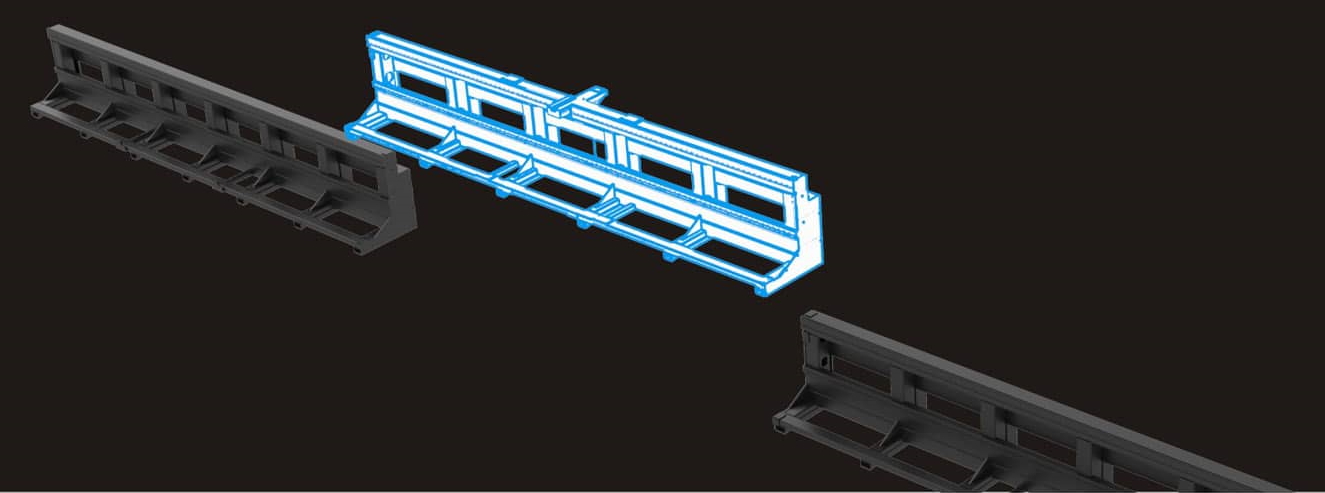

Three-section Machine Bed

The three-section bed design is convenient for transportation; coaxial treatment, high precision and good running performance.

Active Protection System

Anti-collision Protection

The cutting head keeps a safe distance from the cutting surface at any time, and has the function of touch stop function to reduce the risk of collision.

Intelligent Stroke Protection

Auto monitoring of transmission parts’ travelling range transmission parts. The system can give sensitive feedback and quickly command to stop when abnormal, so as to ensure the safety of the equipment.

Intelligent System Alarm

Equipment can conduct self-inspection, main interface can display abnormal alarm, reduce hidden dangers and improve equipment troubleshooting efficiency.

Product Introduction Video

Technical Parameter

| Feature/Model | TL500 |

|---|---|

| Round Tube Processing Dim. | Φ80-Φ426mm |

| Square Tube Processing Dim. | 80*80mm-325*325mm |

| Retangle Tube Processing Dim. | Diagonal≤426mm |

| Profile Processing | Yes |

| Max Single Tube Loading Weight | 1500kg |

| Max Bundle Loading Weight | / |

| Chuck Type | Double hydraulic chucks+ double pneumatic chucks |

| Chuck Max. Loading Weight | 1500kg |

| Chuck Rotating Speed | 30r/min |

| Max. Moving Speed | 40m/min |

| Max. Acc. Speed | 0.3G |

| Positioning Accuracy | ±0.03mm/m |

| Repositioning Accuracy | ±0.03mm |

| Power Protection Grade | IP54 |

| Laser Power | 3000W~6000W |

| Machine Weight | / |

| Machine Weight (loading structure incl.) | 40000Kg |

| Overall Dimensions (L*W*H)) | / |

| Overall Dimensions (L*W*H) loading structure incl. | 30000×5050×3500mm |

*The above data is for reference only, subject to the actual product!