High Quality Carbon Steel Welding Machine Bed

Through simulation and analysis of static and dynamic structural mechanical property design, the main body is welded with high-quality carbon structural steel with tensile strength up to 500MPa.

Full Automatic Double Pneumatic Chuck

One key clamping, automatic centering, 3 times of the speed of the electric chuck;

Pneumatic clamp, large and constant clamping force, no loosening and slipping of heavy tube;

Specialized tube support can avoid tube sagging and deformation, improving the cutting accuracy and extending the service life of the chuck;

Die Casting Magnesium Aluminum Alloy Beam

ZL114A magnesium aluminum alloy is adopted, combined with low-pressure casting process, the crossbeam has large overall hardness, light weight and small inertia; ensuring high-speed operation without vibration.

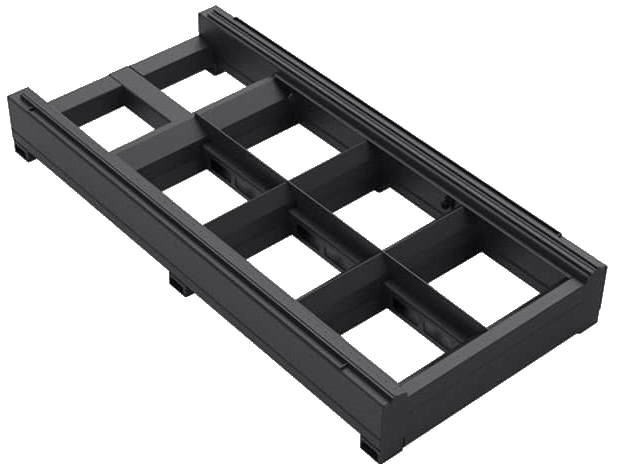

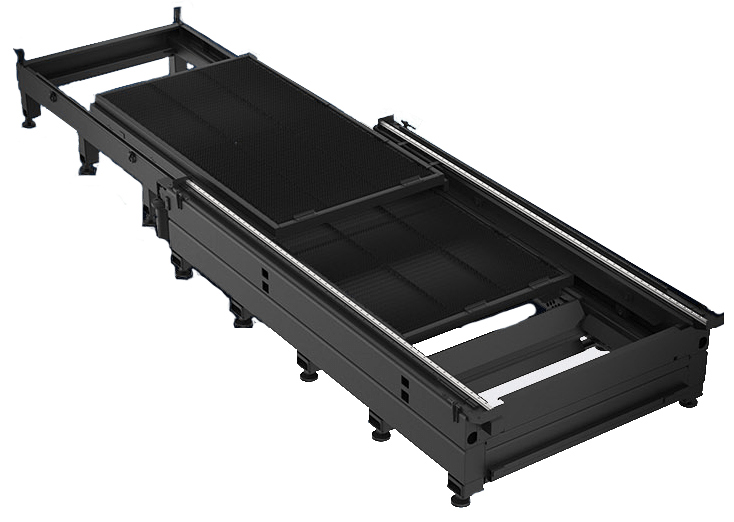

Upper and Lower Type Automatic Interchangeable Table

Independent developed upper and lower type interchangeable worktable, exchange time is ≤ 15 seconds, efficient and saving labor costs.

Simple Operation, Comply with User Behavior Habit

Intelligent Visual Control system

Intuitive adjustment of laser power, gas type and pressure; Intelligent edge seeking, automatic positioning; Support for multi-type file import, intelligent typesetting, automatic generation of sequence, vivid process display;

Intelligent Tube Cutting System

Tube error detection, automatic correction, to ensure the cutting accuracy; Common edge cutting function, reduce material waste, save production costs; Corner cutting technique without over-burnt, good section edge quality.

Intelligent Remote Control

One button wireless control: calibration, blowing, simulation, cutting, pause, etc.; Magnetic suction design, put and take at any time, convenient for operation.

Imported parts, precise control, fast and stable

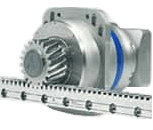

Intelligent Dual Drive

Adopt gantry type with synchronous dual drive servo motor system, ensure the high speed, high precision and high stability of the whole machine during cutting effectively.

Gas Servo Proportional Valve

Imported gas servo proportional valve, digital input, auto regulation, more accurate gas flow and pressure control;

Imported Transmission Parts

Choosing high-end Alpha brand to ensure the high-speed cutting accuracy of the equipment for a long time.

Active protection system

Anti-collision Protection

The cutting head keeps a safe distance from the cutting surface at any time, and has the function of touch stop function to reduce the risk of collision.

Intelligent Stroke Protection

Auto monitoring of transmission parts travelling range. The system can give sensitive feedback and quickly command to stop when abnormal, so as to ensure the safety of the equipment.

Intelligent System Alarm

Equipment can conduct self-inspection, main interface can display abnormal alarm, reduce hidden dangers and improve equipment troubleshooting efficiency.

HSG family design language-- product introduction video

Fully Surrounding Protection

Innovative Integrated Electric Cabinet

Advanced Appearance Design

Technical Parameter

| Feature/Model | G3015E-22EQ | G3015E-35Q | G4020E-22EQ | G4020E-35Q | G6020E-22EQ | G6020E-35Q |

|---|---|---|---|---|---|---|

| Working Area (L*W)) | 3000mm*1500mm | 3000mm*1500mm | 4000mm*2000mm | 4000mm*2000mm | 6000mm*2000mm | 6000mm*2000mm |

| Stroke (X/ Y/ Z Axis) | 1525mm/3025mm/270mm | 1525mm/3025mm/270mm | 2025mm/4025mm/270mm | 2025mm/4025mm/270mm | 2025mm/6025mm/270mm | 2025mm/6025mm/270mm |

| X/Y Axis Positioning Accuracy | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m | ±0.03mm/m |

| X/Y Axis Repositioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| Max. Moving Speed | 60m/min | 60m/min | 60m/min | 60m/min | 60m/min | 60m/min |

| Max. Acc. Speed | 0.5G | 0.5G | 0.5G | 0.5G | 0.5G | 0.5G |

| Round Tube Processing Dim. | Φ20-Φ210mm | Φ20-Φ325mm | Φ20-Φ210mm | Φ20-Φ325mm | Φ20-Φ210mm | Φ20-Φ325mm |

| Square Tube Processing Dim. | 20*20mm-150*150mm | 20*20mm-230*230mm | 20*20mm-150*150mm | 20*20mm-230*230mm | 20*20mm-150*150mm | 20*20mm-230*230mm |

| Retangle Tube Processing Dim. | Diagonal≤210mm | Diagonal≤325mm | Diagonal≤210mm | Diagonal≤325mm | Diagonal≤210mm | Diagonal≤325mm |

| Profile Processing | Yes | Yes | Yes | Yes | Yes | Yes |

| Power Porection Grade | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 |

| Laser Power | 1500W~4000W | 1500W~4000W | 1500W~4000W | 1500W~4000W | 1500W~4000W | 1500W~4000W |

| Max. Loading of Sheet | 800kg | 800kg | 1400kg | 1400kg | 2000kg | 2000kg |

| Max. Loading of Tube | 100kg | 100kg | 100kg | 100kg | 100kg | 100kg |

| Machine Weight | 8900kg | 9900kg | 11500kg | 12500kg | 13250kg | 14250kg |

| Overall Dimensions (L*W*H)) | 9550×3900×2650mm | 10200×3900×2650mm | 10650×4450×2650mm | 10650×4480×2650mm | 15250×4450×2800mm | 15250×4450×2800mm |

*The above data is for reference only, subject to the actual product!——–Click the left and right buttons on the above picture to view more.